AC System

Absence of light is darkness similarly absence of heat is cold

HOW CAR AIR-CONDITONING SYSTEM WORKS?

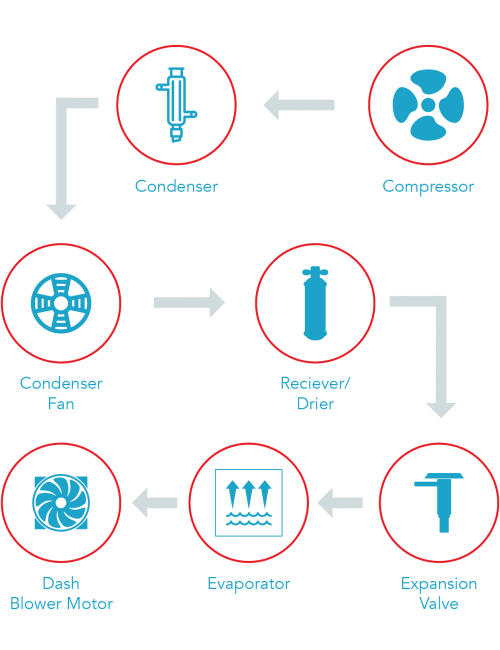

Absence of light is darkness similarly absence of heat is cold. So the primary job of any air-conditioning system is to remove heat to give the experience of cold feeling. Heat is removed or absorbed by the evaporator (it is called evaporator as the liquid refrigerant evaporates to vapour absorbing heat from

the surrounding) located in the cooling unit or HVAC behind the dash board. So basically this is heat exchanger number 1. This absorbed heat is then released at the condenser where condensation takes place as the vapour refrigerant becomes liquid again losing all heat (which was absorbed from the

passenger cabin) this is heat exchanger number 2. The liquid refrigerant then enters the evaporator again and the cycle thus continues. The compressor is a pump used to circulate the refrigerant between the 2 heat exchangers which are connected by hoses or tubes. Another 2 critical components are the

expansion valve at the evaporator and the receiver drier. Name of the part explains the function of the part, the expansion valve is where the liquid refrigerant expands from liquid to vapour and the receiver drier located after the condenser or in the condenser where the liquid refrigerant is cleaned / dried. Please see the diagram below __

FAQ's

Car air-conditioning service is not a part of the routine service. As explained above keeping the 2 heat exchangers clean is the key for satisfactory performance of the air-conditioning system. The condenser is mounted in front of the radiator on the front of all cars. Dirt and dust from the road enters and clogs the condenser and thus its performance diminishes over time. Similarly the evaporator is located in the dash board / HVAC , here the cabin air circulates or passes through it as it gets cold. Along with the air dust and dirt present is the flooring mats, carpet is sucked and passes through the evaporator. In humid climatic conditions this evaporator gets wet as it also acts as a dehumidifier and one sees water drop lets falling out from the drain tube. The dirt and dust thus present in the car cabin gets stuck on this wet

evaporator and chokes it over a period of time. Fungus, bacteria breed in this area which is wet and full of sticky dust resulting in foul smell when you start the air-conditioning system. Hence it is required to clean both the heat exchangers routinely every 15000kms or two years whichever is earlier. If our room air-conditioners or even our ceiling fans require cleaning every 3 to 4 months imagine the condition of the car air-conditioning system that runs on road and exposed to such dirty and dusty condition. Please the before and after photo below___

The both heat exchangers get choked which results in poor or lesser cooling during day time when the heat load is more. The same air-conditioning performs reasonably well during evenings of nights. Timely servicing or cleaning of both these heat exchangers will ensure cooling efficiency.

As explained above the refrigerant gas is circulated in the air-conditioning system and is not consumed, so unless there is leakage from any component or pipe or joint o ring. The hoses in the air-conditioning have very low permeability rate. Like your car tyre even if there is no puncture yet you have to top up air to maintain the air pressure , similarly the refrigerant requires to be topped up only that to over very long period of time as the permeability ratios are very low. During service usually the compressor oil and the refrigerant is freshly charged.

The simple answer is NO. Modern cars air-conditioning systems are designed to give optimum performance at optimum refrigerant charge. Lesser or more refrigerant gas affects the performance of the system and could cause permanent damage to the air-conditioning system. So it is very important that the refrigerant gas charging by done using appropriate refrigerant recharging machines which do exact charging as prescribed by car manufacturers.

Since the air-conditioning system not only removes the heat from the air in the car cabin but it also dehumidifies the air, resultant water dripping from the evaporator / cooling unit drain tube. So the evaporator unit remains wet and has water in the fins and also in the lower tray. This water remaining causes oxidization on the aluminum tubes and eventual leakage due to corrosion.

Yes you could delay or prevent the evaporator from corrosion this by drying the evaporator after every usage. For this you need to switch off the compressor and keep the blower on for few minutes before switching off the car once you reach your destination. Lesser the water remaining in the evaporator or lower tray, lesser is the chance of corrosion.

The failures of compressor on the modern cars are far lesser with the advent in technology and quality of material used. Most of the modern cars are equipped with variable displacement compressor for better fuel efficiency and lower compressor clutch failure. In our experience most of the cars that reported to us for compressor failure turned out have a compressor control valve failure. After replacing the control valve which cost marginal the compressor functioning has been restored. There are cases of compressor leakages which could be addressed if the seal kit and o rings are available. Compressor

could also fail if the compressor oil has not been checked (top up required) /changed during air-conditioning servicing. Another reason for compressor failure could be inappropriate running temperature which could be due to overcharging of gas or higher discharge pressure/ temperature. During air-conditioning servicing all this is checked and looked at to avoid failure of major components.

Compressor is like an engine and has pistons, only that these pistons do not have rings. Instead they are quoted with a special compound like Teflon which ensures that the piston is tight fit in the chamber and ensures the compression in the suction and discharge stroke. When poor quality or incorrect grade oil is

used, metal flakes from bearing failure or reed breakage come in the compression chamber they cause damage to the bore resulting in the damage to black coating on the pistons. The resultant black sludge then circulates through the air-conditioning system contaminating the entire system. This is failure of compressor is called “black death” of the air-conditioning system. Flushing of systems damaged with “black death” is not advisable as the condenser / evaporator fin tubes have multiple pass and hence there is no assurance or guarantee of proper flushing. At the most the pipe lines and tubes could be cleaned of contamination; the rest of the system needs to be replaced.

Knowledge of the subject, proper tools and trained manpower along with prescribed method of working are the key to satisfactory completion of any job. Simran System is authorized by companies manufacturing air-conditioning systems that are supplied to car manufacturer. They not only have the proper trained experienced manpower but also have the tools and machinery required for doing the service, repair and diagnosis. Services of Simran Systems are utilized by OEM’s, authorized dealerships, fleet owners, corporates and even individual customers. 35 years of experience and zero repeat job makes Simran Systems the best choice for your car air-conditioning service requirements. The compressor technology has also come a long way from fixed displacement compressors to variable displacement compressors, from electromagnetic

clutch to clutch-less variable displacement compressor. Unlike the old Fixed Displacement Compressor (FDC), the Variable Displacement Compressor (VDC) automatically varies its pumping capacity to meet air-conditioning demand as per the temperature selected inside. When the car’s cabin temperature is high, it increases its pumping efficiency (displacement) until the desired temperature is reached. Once the desired temperature is reached it

automatically reduces its displacement to maintain the desired temperature. Hence knowledge, skilled person, appropriate diagnostic tools and working process are the key for quality “first time right” repairs and servicing. All of this is what SIMRAN SYSTEMS have to offer.